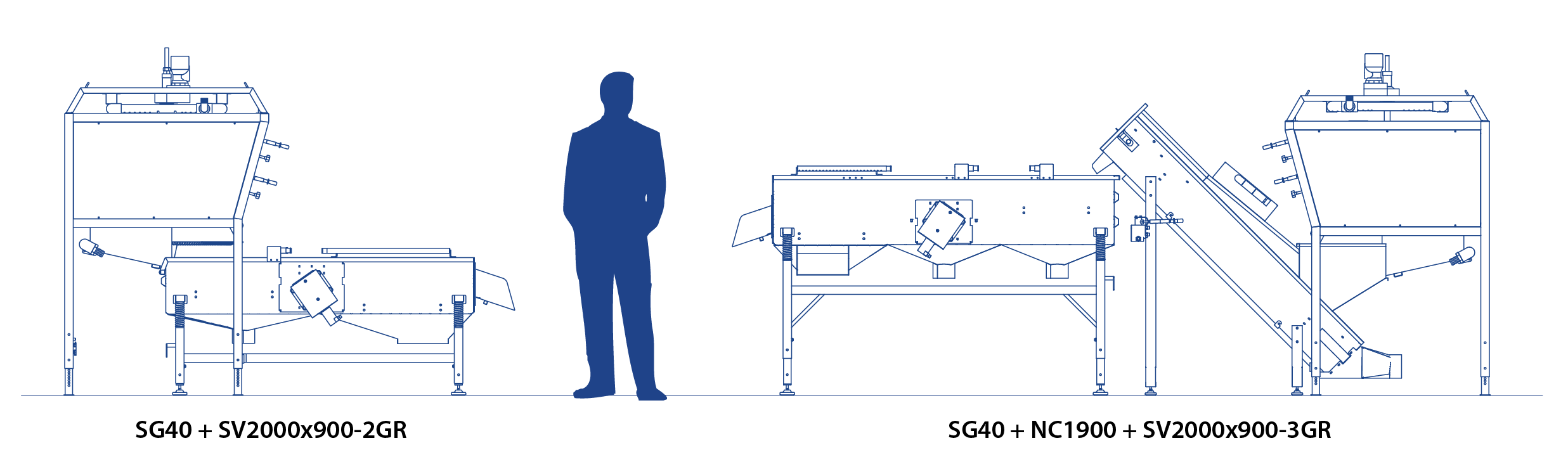

The declumping line for mussel farming allow the separation and resocking of harvested mussels, giving also in an excellent cleaning of the product carried out by two sets of brushes mounted on the declumping machine. Thanks to the embedded washing system, our declumping machines eliminate the majority of the mud, impurities and of the mussel seed that might be present on the grown harvested product. The vibrating grading machine and the resocking belts at the end of the line allow the re-socking of the product in a double tubular net made of plastic and cotton mesh.

Our company is the world's only manufacturer that can produce 3 different models of declumping machine, differing in dimension and productivity (up to 6 Ton/h), and grading machines that are extremely customizable in function and size, so that everyone can find the perfect solution for his business, from individual mussel farmers managing a few lines to companies working with multiple vessels on the same farm.

The materiales utilized in the construction of this machine, as for every other machinery built by our company, are especially dedicated to the use in the marine environment and in the harshest conditions: the structure of the machine is made of Aisi 316L stainless steel, and high resistance plastic material suitable for the contact with food, all in line with the European Community regulations for the food processing sector.

- Product categories:

- Suitable for: