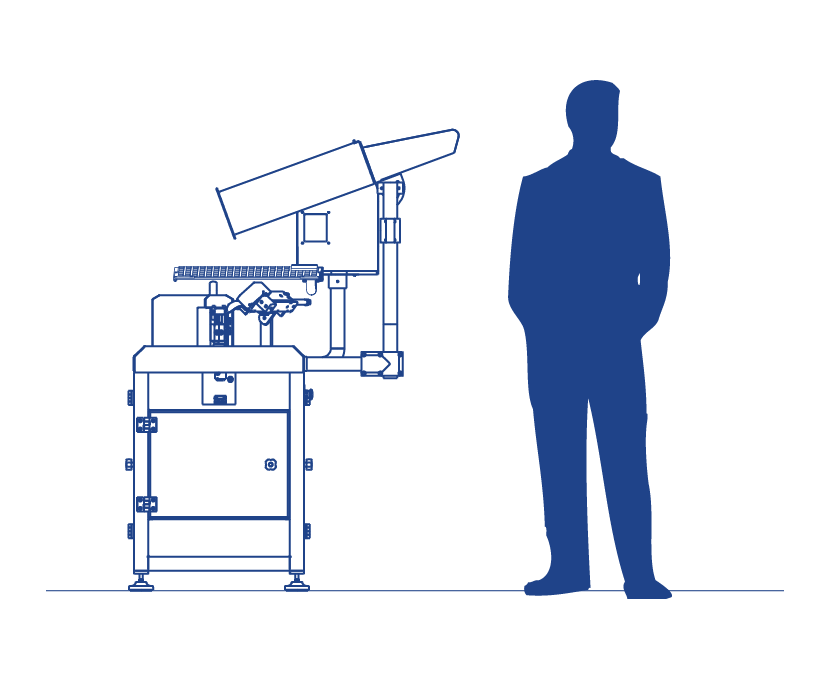

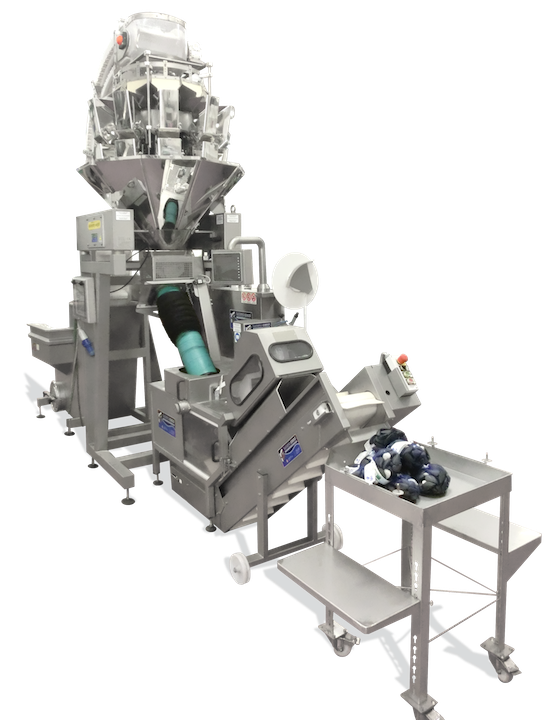

The manual clipper with thermal printer is a machine for the tight closing and labeling of bags of small quantities of shellfish (0,5 to 3 kg) or of short pieces of mussel socks. When the product enters the infeed pipe pre-loaded with plastic tubular net, the operator catch it from the other side of the tube, tighten it manually, and make it pass through the clipper to begin the clipping cycle. At every cycle, the machine seals the net with 2 clips created from rolls of galvanized wire and cut it in the middle of the closures, automatically printing and attaching a tag label with the product data. An automatic lubrication system protects the mechanisms of the clipper and keeps them fully functional in time.

The thermal printer allows to write all the data regarding the product to be packed on tag labels pre-printed with the logo of your company, as required by the local sanitary regulation (for example scientific name, catch zone, packing date, lot number, barcode, etc.). The product to pack can be set through a waterproof qwerty keyboard made in high resistance plastic material. The thermal printers stores the product data in an internal database, that can easily be modified using a proprietary software on any computer, and updated using a simple USB key.

The printer has also an Ethernet port, through which it can be connected to the company network and to management software for the traceability of the product. A stainless steel cover protects the printer, that is an industrial model with a solid structure made of metal and high resistance plastic material, ready to be used in the harshest environments. The manual clipper cut the printed label and seal it firmly on the bag together with the galvanized wire clip, all in one operation.

The materiales utilized in the construction of this machine, as for every other machinery built by our company, are especially dedicated to the use in the marine environment and in the harshest conditions: the structure of the machine is made of Aisi 316L stainless steel and plastic material suitable for the contact with food, all in line with the European Community regulations for the food processing sector.